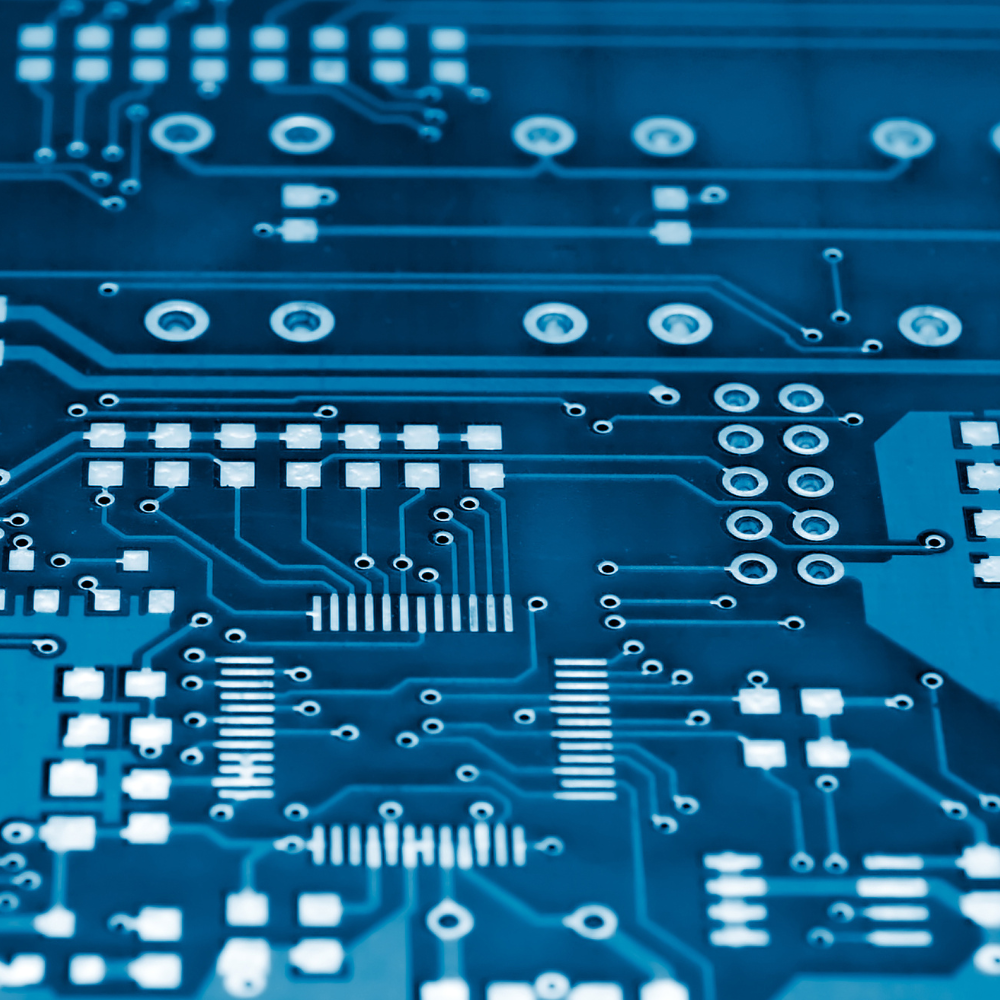

The Fascinating World of Printed Circuit Boards: A Deep Dive

Printed Circuit Boards (PCBs) are the backbone of the modern electronics industry, serving as the foundation for virtually all electronic devices we use today. From smartphones and computers to medical devices and automotive systems, PCBs make the integration and functionality of complex circuits possible in compact spaces. This blog post will explore the intricacies of PCBs, their evolution, manufacturing processes, types, and their critical role in the advancement of technology.

The Evolution of PCBs

The concept of PCBs dates back to the early 20th century, but it wasn't until the 1950s that they became a staple in electronic manufacturing, replacing the traditional point-to-point construction. The introduction of PCBs marked a revolution, allowing for more reliable, compact, and cost-effective electronic devices. Over the decades, advancements in materials, manufacturing techniques, and design software have significantly improved the performance and reduced the size of PCBs, enabling the miniaturization and sophistication of electronic devices we witness today.

How PCBs Are Made

The manufacturing of PCBs is a meticulous process that involves several steps, each critical to the functionality and reliability of the final product. The process typically starts with the design phase, where engineers use specialized software to layout the circuit. The design is then transferred onto a copper-clad laminate, which undergoes a series of processes including etching, drilling, plating, and solder masking, to create the desired circuit pattern. The complexity of the manufacturing process depends on the type of PCB and its intended application, ranging from simple single-layer boards to complex multi-layer designs.

Types of PCBs

PCBs come in various types, each suited for different applications and complexities of electronic devices:

- Single-Sided PCBs: These are the simplest type, featuring a single layer of substrate and conductive material, ideal for low-density designs.

- Double-Sided PCBs: These boards have conductive copper layers on both sides, allowing for a higher density of circuits.

- Multilayer PCBs: These are composed of three or more double-sided boards stacked together, offering higher circuit density and improved performance characteristics, crucial for advanced electronic devices.

- Flexible PCBs: Made from flexible materials, these PCBs can bend and flex, making them ideal for devices where space and form factor are constraints.

- Rigid-Flex PCBs: Combining the features of rigid and flexible PCBs, these boards provide the best of both worlds, offering durability and flexibility in complex applications.

The Role of PCBs in Technology Advancement

PCBs have been instrumental in the rapid advancement of technology. They have enabled the development of smaller, more powerful, and energy-efficient devices, pushing the boundaries of what's possible in electronics. In sectors like healthcare, PCBs have led to innovations in medical devices, improving diagnostics and treatment options. In the automotive industry, they are at the heart of electronic systems that enhance vehicle performance, safety, and comfort. The IoT (Internet of Things) revolution is also heavily reliant on PCBs, connecting billions of devices worldwide.

Conclusion

Printed Circuit Boards are more than just layers of copper and substrate; they are the critical infrastructure that powers the digital age. As technology continues to evolve, the importance of PCBs in enabling innovations and driving advancements in various industries cannot be overstated. The ongoing research and development in PCB design, materials, and manufacturing processes promise even more exciting possibilities for the future, ensuring that PCBs will continue to be a cornerstone of electronic engineering for years to come. Whether you're a tech enthusiast, an engineer, or just curious about the electronics that power your daily life, the world of PCBs offers a fascinating glimpse into the building blocks of modern technology.